You are here

LED Lamps Made in America

Contract manufacturers who have good equipment and a modicum of expertise in the use of that equipment can populate LED boards with little trouble. The ‘rub’ comes when the customer wants more than simple LED placements, like quality blank board sourcing, like LED and driver circuit sourcing from reliable sources that can guarantee genuine parts at the right price and delivery order after order, and dependable and careful attention to binning of LEDs. intricate conformal coating, lenses installed properly and wire leads soldered neatly onto the boards. Finished LED boards are frequently not in a rectangular configuration, due to their ultimate application. Some boards are serpentine, some are long and skinny and still others are circular. And of course everyone needs their boards quicker than you can possibly get them done. A screw up in any one of these areas and you can wind up with a lot of boards that don’t live up to your expectations and an unhappy relationship.

Let’s look at each one of these challenges for opportunities. (1) Metal clad boards can be purchased from a variety of sources, but we have found that consistently high quality boards at an affordable price and reasonable delivery is quite another matter. As everyone in the industry knows, board manufacturing is a very, very tricky and expensive business. There are chemical etching solutions to deal with, both in the process as well as the disposal of or recycling of waste streams created by the process. Then there are optics, and soldering, and curing of the masks, etc. Even with the latest process controls and procedures developed over the past several decades, it is still difficult to keep consistent quality. So it is imperative that the assembly house know the supplier so that quality board material is used for the application and the best board house to manufacture your boards. (2) Sourcing quality LEDs and ancillary components that are guaranteed to be non counterfeit is a feat in and of itself. Finding a reliable supplier that can provide assurance of genuine parts at the right price, with no mixed bins and can deliver them order after order takes time to develop and maintain. (3) Next consider conformal coating. Some customers need the finished board to be conformally coated, but you usually do not want the conformal coating to cover the LED lens, least you affect the lens by reducing light output or distorting the LED’s output color and/or intensity. The coating can be applied by human hand or a machine. The decision of who or what does the coating will depend on the quantity of boards to be done. Since it can take quite a bit of time to program the machine, a few will likely be done by hand, whereas a large quantity will likely be done by machine. Successful hand application is tricky and requires very skilled and trained people to do it successfully. (4) All LED boards need either connectors and/or wires for connecting them into the fixtures. The very small connectors in use today can be easily contaminated with the conformal coating collecting in the connector. The selective coating which is generally cured with heat must be applied in such a way as to not cover solder pads where wires are to be soldered in the final step. Then there is the matter of testing the finished product to determine if all LEDs are functioning without blinding the tester. Testing for color and intensity is also frequently a requirement.

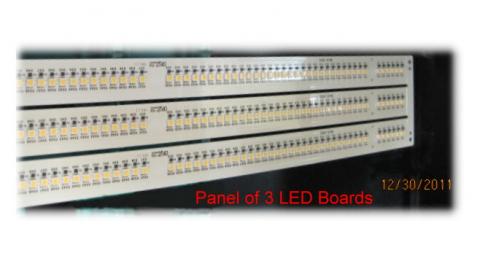

Many LED boards are very small and labeling for date code and part number can be a challenge. Of course on the other hand long skinny boards are common as we begin to replace fluorescent bulbs with LEDs. They present still other challenges. So the assemble of LED boards is more than simply placing LEDs on a standard board.

At Global Manufacturing Services, Inc. we have been building power LED boards for the lighting industry as well as LED boards for the signage industry for a number of years and have solved many of the challenges of this exciting industry. If there are LED boards in your plans, please call us and let’s discuss your application. I am sure you will be pleased with what we have to offer.